UPA-A is introducing a new lab-based stress test designed to mimic the effects of paddle degradation over time.

It's an accepted fact that the performance of many pickleball paddles changes over time. As core materials break in, power, pop, and spin can increase.

Sometimes, this change is noticeable at first but then plateaus within what feels like a normal range. Other times, the paddle put in hands of consumers changes drastically from what was originally approved–see exhibits A, B, and C–to levels outside of what's permitted.

But how do you test for a subjective probability like that, with so many existing paddles and new models being introduced at the pro level all the time? How to you emulate months of game-play before a paddle has hit a single ball?

For the UPA-A, the governing body of pro pickleball, the answer lies in a new standard: the Artificial Break In Standard (ABI).

Breaking Down the UPA-A 2025 Pickleball Paddle Guidelines

The United Pickleball Association of America (UPA-A) has announced pivotal updates to paddle regulations, effective September 1, 2025, aimed at ensuring fairness and consistency in professional gameplay. With the recent formation of the UPA-A, players have been anxious to see how the organization would handle the issues related to paddle

The Dink PickleballLuke Burton

The Dink PickleballLuke Burton

What is ABI?

The UPA-A works with a third-party testing laboratory, Pickle Pro Labs (PPL). After a "months long investigation" into the break-in periods of paddles, this new ABI standard has been created.

The gold standard is measured by Paddle Efficiency Factor (PEF), a metric that evaluates a paddle's power output by measuring how efficiently it transfers energy to a ball during play.

As previously announced, effective September 1, 2025 all UPA-A paddles must meet the 0.385 PEF standard when new and must also not exceed a PEF ceiling of 0.405 after undergoing a standard break in procedure.This new "standard breaking in procedure" is where ABI comes in.

ABI is a process that physically breaks down the structure of a paddle in a controlled and systematic manner such that it does not result in visible damage to the paddle. The performance gain resulting from the ABI process is measured through subsequent PEF testing.For 2025, the UPA-A is capping the ABI, meaning each paddle is only broken in to a predetermined threshold–which is a function of the paddle's thickness.

UPA-A to Use ‘Destructive Testing’ to Level the Pro Playing Field in 2025

The UPA-A will use “destructive testing” to determine whether or not a paddle can be used in pro pickleball events starting in 2025. Find out what that test is and how it could shape the PPA and MLP.

The Dink PickleballAlex E. Weaver

The Dink PickleballAlex E. Weaver

How Does it Work?

This all gets pretty technical, but here's a general breakdown.

According to a white paper published April 11, 2025, Pickle Pro Labs uses ABI in conjunction with Average Deflection Force (ADF) and paddle-ball coefficient of restitution (PBCOR) to evaluate changes in paddle performance.

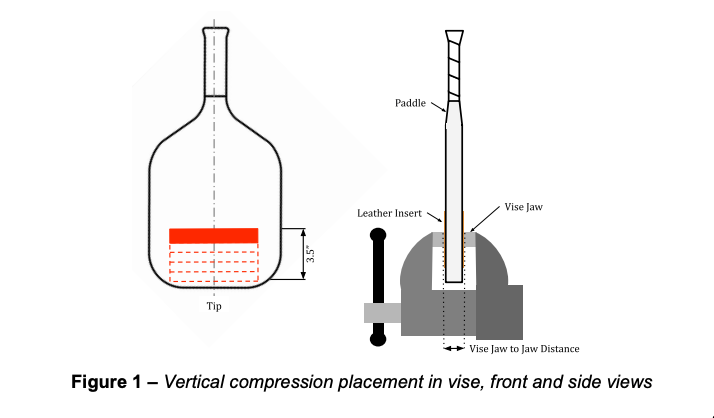

Given the potential for paddles to dramatically increase in performance through the break in process, a standardized method is needed to break paddles in so that any increased performance can be readily determined.The ABI method uses a vice, with each side covered in a specific type of industrial-grade leather insert.

The vice is then clamped at pre-determined intervals across the paddle's face (the "Compression Cycling Method") using very specific levels of force, beginning 3.5 inches from the tip of the paddle, as shown below.

This process is then repeated across multiple points on the paddle's face–both at its core and along the perimeter–with the paddle secured both vertically and horizontally. "At minimum," the standard states, "15 Compression Cycles should be completed per location on paddle."

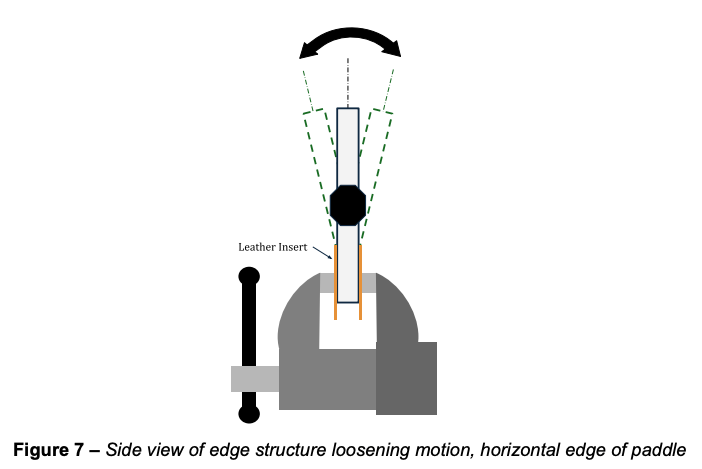

Once complete, an "Edge Cycling Method" applies 10 to 15 degrees of force in both directions to the topmost portion of the paddle to determine if there's been any structural decomposition. This motions is repeated at least 20 times.

"There may be cracking and popping noises," the white paper stresses. "These noises are acceptable so long as the paddle face shows no visible signs of damage."

Love pickleball? Then you'll love our free newsletter. We send the latest news, tips, and highlights for free each week.A Few More Notes

The white paper provides a few important clarifying notes:

First:

The purpose of ABI is to break down the paddle structure in an even and systematic fashion. The process described in this document involves a human operator and inherently has variability. An operator will become more skilled in this process with repetition.Second:

An automated ABI process that will improve the efficiency, effectiveness and repeatability of the ABI process is currently in development and is expected to be introduced in the coming months. The new method will also make it more practical to implement useful-life testing of paddles, rather than the fixed displacement process described in this document.Why This Matters:

Here's what the UPA-A thinks:

For manufacturers:

The capped ABI creates a conservative and standardized benchmark for paddle break in.For players:

It ensures no paddle gains unfair power over time without being identified by onsite testing.For the sport:

It puts us on a path of improved competitive integrity by confirming that certified paddles do not break in at an uncontrolled rate.The regulation of paddles at the recreational and professional levels continues to be a hot-button issue among the sport's governing bodies and paddle manufacturers.

One Sport, Two Standards: The Battle for Control of Pickleball

Six industry leaders convened at RacquetX in Miami for a discussion around the current fragmented state of regulation in the sport.

The Dink PickleballErik Tice

The Dink PickleballErik Tice

What Do Paddle Brands Think?

We reached out to a couple paddle brands to get their thoughts; here's what a few had to say.

Garrett Gosselin & Kyle Goguen

Co-Founders: CRBN

"We applaud UPA-A — or any governing body — for taking steps to ensure paddles don’t gain unfair performance through wear. A level playing field is essential, and as long as testing is transparent, fair, and free of loopholes, we’re fully on board. We hope this new standard encourages other brands to move away from paddles with a meaningful break-in period and helps move the sport we all love forward."

David Groechel

Founder: 11Six24

"While I view the UPAA's implementation of destructive testing as a positive development, it addresses a concern that was more prevalent 1-2 years ago. Today, most established manufacturers have already improved their durability standards, as market forces naturally eliminate paddles with recurring breakage issues from consumer consideration."

Anuncie Aqui / Advertise Here

Sua marca para o mundo Pickleball! / Your brand for the Pickleball world!

English

English  Spanish

Spanish  Portuguese

Portuguese  German

German  Italian

Italian  Japanese

Japanese  French

French  Polish

Polish  Russian

Russian  Netherlands

Netherlands  Hungarian

Hungarian  Turkish

Turkish  Videos

Videos

English (US) ·

English (US) ·  Portuguese (BR) ·

Portuguese (BR) ·